Until just five months ago, Canadian entrepreneur Ed Shim’s mission was clear: to improve the patient health-care experience – through better bedsheets. Then came the pandemic. In the new COVID economy, Shim saw both the need for a creative pivot and the opportunity to address the acute global shortage of protective medical equipment.

A smarter bedsheet

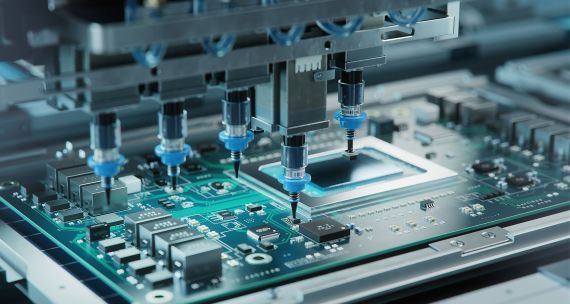

Shim, co-founder and Managing Director since 2015 of Markham, Ontario-headquartered tech start-up Studio 1 Labs, is the inventor of advanced fabric sensor technology used in clinical-grade intelligent textiles. Used as a sheet, the smart fabric is scientifically validated to detect physiological signals from a body lying on it non-invasively. Without wires, cameras, or physical attachments, pressure and vibration sensors within the sheets continuously monitor vital signs such as respiratory rate, rhythm and effort, heart rate, sleep patterns, and movement. Not only do the sheets gather in one-shot data that otherwise requires multiple devices to collect, but by monitoring health trends over time, they can assist in predicting the onset of health decline and crises, such as heart attack or stroke.

A partner in Taiwan

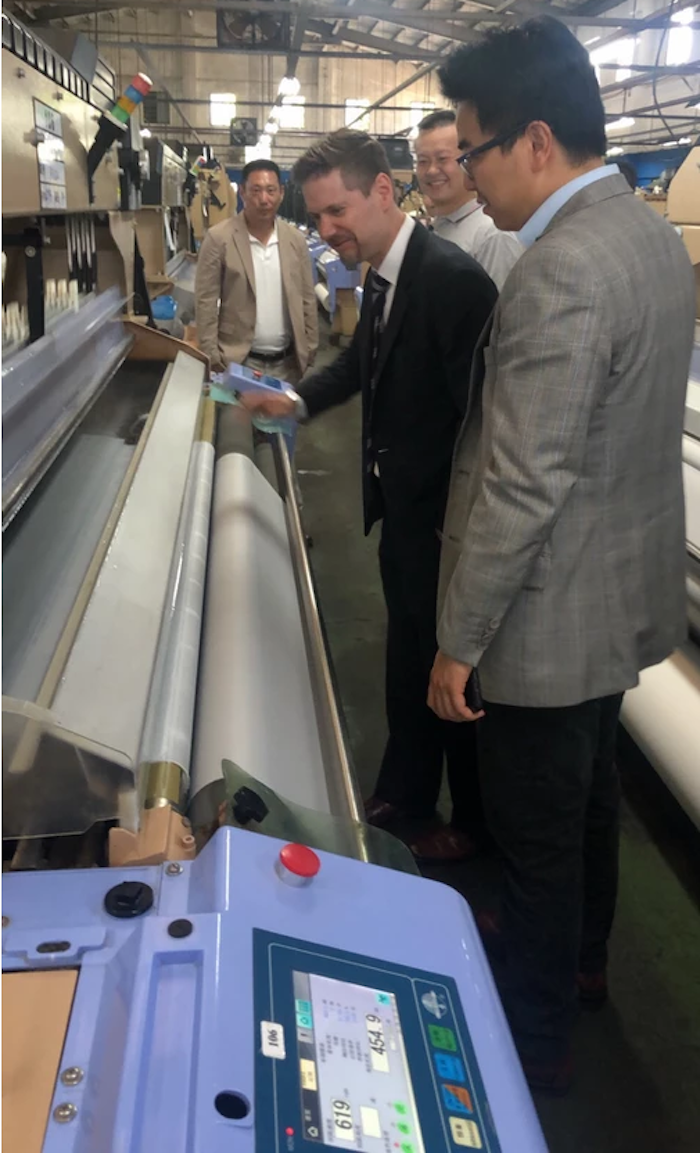

When, after several years of testing and reconfiguring, Shim began looking for a manufacturing partner, his eyes were on Asia. The plan was to assemble and produce the smart sheets at home, creating jobs for Canada’s diverse talent pool, but to manufacture the raw materials elsewhere. He needed a company familiar with the emerging smart textile industry and able to satisfy his need for constant iterations. In 2018, Shim found that partner in Taiwan, where functional textile production is a strength, and a support system already existed for finding corporate partnerships. Shim was advised he would need to raise C$650,000 to cover manufacturing costs in the United States, but found his Taiwanese manufacturer willing to invest heavily through in-kind contributions, essentially covering the cost of production. The relationship was strong from the beginning, Shim notes, and only grew stronger with COVID-19.

Shim praises the flexibility and speed of his Taiwanese partners, who rapidly produced iteration after iteration in response to evolving specification changes. For example, as the COVID crisis prioritized the need to measure respiratory distress, Shim transformed his full sheet design into smaller intelligent bed strips, which are placed under the torso to record respiratory trends. Smaller strips are currently being sold as a custom product in the U.S. to train physiotherapy students by providing real-time feedback about pressure standards. Shim hopes to begin shipping the strips to Canada soon for use as COVID symptom monitors.

In addition to a climate ripe for production, in Taiwan Shim found a government eager to support enterprises like his. He has remained in Taipei throughout the pandemic, thanks to the flexibility of the Taiwan Entrepreneur Visa. Recognizing Studio 1 Labs’ value to Taiwan’s textile industry even before COVID-19, the Taipei City Government helped facilitate his visa application, making him one of the very first recipients of this visa specifically for foreign investors. Though he plans to return to Canada soon for the first time in five months, he will be able to continue travelling between Canada and Taiwan due to an additional two-year visa extension.

From sensors to protectors

When the novel coronavirus hit, Shim reassessed his business plan: rather than focusing on the sensor technology, which was still several months from being commercially production-ready, he could adapt his fabric to satisfy a new global need. Given the harsh clinical environments the fabric had to be able to survive, durability was a vital component in development. Shim had considered improving the sensor’s resistance to chemical disinfectants but opted instead to focus on creating a hard-wearing fabric outer layer. It occurred to him that this durable, pre-tested fabric cover could have applications as Personal Protective Equipment (PPE), specifically for reusable medical gowns.

While it took years to develop the fabric, repurposing the technology from bedsheets to gowns took only weeks. This was due to various factors, including the responsiveness of his manufacturer, as well as the foundation of product development and relationships built through Studio 1 Labs’ access to government resources, and university and industry partners. The eco-system Shim has built in Canada over the past five years through programs and partnerships was vital in rapidly identifying and testing for a full set of medical gown criteria related to such characteristics as impact penetration and hydrostatic pressure. “When COVID hit, we acted quickly because all the infrastructure was established,” says Shim. “It was a simple pivot.” In early June, Studio 1 Labs sent its first PPE materials shipment from Taiwan to Canada. Throughout June, plane shipments left almost daily, and boat shipments almost weekly, with about 1.5 million yards of fabric in total arriving in Canada for assembly.

Supply chains and patents . . . keys to success

One of the most valuable lessons Shim has learned on his start-up journey has been how fragile supply chains can be and how vital it is to diversify. “It’s not limitation of funds that destroys companies,” he says, “it’s limitation of options.” Challenges completely beyond a business’s control, such as political tensions, trade wars and tariffs, broken partnerships and even, as we now know, pandemics, can destroy supply chains and cripple companies. To increase his options, Shim has established relationships with potential suppliers and producers in several countries in Asia, the EU and the U.S. If high costs or an event such as COVID make it impossible to operate in one region, he knows he has back-ups.

A firm believer in the power of the patent, Shim retains control of his initial technology and has consistently rejected offers from partners pressuring him to sell or relocate his patent rights. “Canada is strong at innovation,” he says. “The problem is we don’t concentrate on the value of intellectual property, and patent technology gets sold, so the strength of the company suffers, and we end up buying the tech back at a higher price.” The ability to leverage usage rights for his technology offset the need to raise millions in private capital and was essential to getting his products to market. Resisting the temptation to sell his patents for quicker financial return made the process longer and more challenging, but the end product would not be where it is today otherwise. Hoping to help other Canadian innovators, Shim is lobbying the federal government to make patent fees, currently not considered a direct research cost, an eligible expense under grant funding usage regulations.

Support from Canada

Shim credits much of Studio 1 Labs’ success to the support he has received in Canada from government, academic, corporate and not-for-profit institutions and from the resulting network of relationships. Aside from the obvious immediate benefits, receiving funding from government sources – including the Ontario Centres of Excellence (OCE), the Natural Sciences and Engineering Research Council (NSERC), and the National Research Council Canada (NRC) – was a strong validation of his technology, which encouraged corporate partners to support major expenses such as software infrastructure costs. In 2018, Shim was nominated by the Asia Pacific Foundation of Canada to travel as a delegate on the Kakehashi Project, a Canada-Japan exchange program for young business leaders funded by Japan’s Ministry of Foreign Affairs. The trip opened his eyes to how little he, the Canadian-born and -raised son of Asian-born parents, knew about Asia and gave him a new perspective on the strengths of Canada’s diversity of culture and talent. The experiences he had doing business face-to-face in Japan proved invaluable in paving the way for his successful encounters in Taiwan. Shim feels these kinds of soft-landing programs are even more important in helping entrepreneurs gain experience across the Asia Pacific and position them to move quickly in times of economic and health uncertainty.

The COVID marketplace

Shim sees opportunities for Studio 1 Labs to grow and to do good in the COVID business climate beyond supplying PPE. The capacity of the bedsheets and strips to register breathing struggles and lapses fills a gap in existing diagnostic technology, providing an early warning system for respiratory distress with the potential to improve COVID outcomes. Also, diversification being imperative in today’s economy, Shim is working on various other projects, including next-generation anti-viral fabrics for enhanced medical gowns and mask filtration systems.

A firm believer in Canadian talent resources, Shim is currently concentrating his efforts on encouraging partners in Taiwan and Canada to commit to a hiring exchange program for students from both countries. With project approval from SOSCIP Smart Computing for Innovation and affiliations at universities in Canada and Taiwan already in place for a COVID research study, Shim is helping to promote the development of a severity index for lung function deterioration, and hoping to find Canadian students interested in the opportunity to study in Taiwan.